MoistTech Moisture Sensor Applications

With over 40 years in the moisture management industry, MoistTech developed the IR-3000 online NIR sensor for instant, non-contact measurement of many products and raw materials in the harshest manufacturing environments. Continually monitoring and controlling moisture levels allows operating personnel to confidently make immediate process adjustments based on realtime measurements.

With experience in thousands of applications globally and thousands of equipment installs, MoistTech represents the diamond standard in robust, reliable, and dependable technology for harsh environment process measurement and precise product control. Production efficiency improvements due to accurate realtime measurements provide both energy savings and potential increased productivity with lower material losses.

Performance Guarantee – If MoistTech equipment does not perform to your specifications within 30 days of operation, it can be returned for a full refund, less the cost of return shipping.

What is NEAR INFRARED (NIR) TECHNOLOGY?

All molecular bonds absorb specific wavelengths of light. Hydrogen bonds including O-H (water); C-H (hydrocarbon) and N-H (ammonia) all absorb strongly in the NIR spectral region. The amount of NIR energy reflected at a given wavelength is inversely proportional to the quantity of absorbing molecules in a product.

The NIR technique is a non-destructive, noncontacting measurement. MoistTech’s sensor utilizes multiple wavelengths of NIR light, projected onto the product at a very high repetition rate. The reflected light is then measured using a digitally enhanced detection system and thousands of data points are sampled every second.

The Benefits of Moisture Control Video MoistTech FAQ IR 3000 brochure

MoistTech vs Competitor Tech Ethanol Moisture Control Benefits 4 Steps to Moisture Control Video

Animal Foods

Stable, fixed moisture levels ensure that animal food products maintain consistency and that product waste is minimized. Too wet or too dry food results in a manufacturers wasted time and money. With MoistTech IR-3000, you can watch production costs without cutting quality. The MoistTech instrument measures and regulates moisture in animal products and helps you eliminate product waste and downtimes.

Bioenergy

Bioenergy

When it comes to wood chips, pellets, saw dust, hogfuel, and waste fiber, excess moisture can ruin products. MoistTech’s IR3000 makes it easy to control moisture levels, avoiding wasted time and money.

Chemical

Chemical

Testing chemical moisture content throughout the chemical manufacturing process provides cost savings in energy, fuel costs, and loss of product. With MoistTech’s NIR continuous online moisture testing, manufacturers can closely monitor moisture levels and precisely control the production processes.

Having extensive experience with requirements in chemical production processes, MoistTech’s chemical moisture sensor calibrations, measurement wavelengths, algorithms and optical requirements are preset at the factory, making the sensor easy to set up and providing instant measurement of your product.

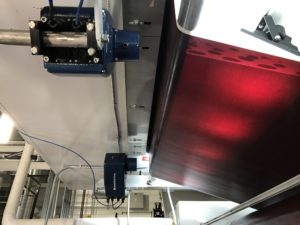

Converting

Converting

Paper can easily become too wet or too dry, making moisture monitoring critical to production. With MoistTech’s IR3000 moisture sensor, manufacturers can measure and manually or automatically control moisture levels as well as water and solvent based coatings during the paper/converting process, improving product quality and increasing productivity which, in turn, means substantial cost savings.

Grains

The moisture content of grain must be kept at the perfect level in order to yield the highest return. Too moist, and the grain will spoil in storage; too dry and the reduced weight will lessen its value. The key is to retain the most moisture possible, while staying under the suggested moisture levels.

Each type of grain is different, so a working knowledge of the moisture levels acceptable for each is necessary. Proper instruments for measuring the moisture level with accuracy are also necessary. With MoistTech sensors, moisture can be regulated during each production step – from processing to storing.

With varying moisture content in grains, on-line Near-Infrared (NIR) moisture management technology is key in ensuring optimum efficiency and quality control. The ability to measure moisture and make process adjustments during the production cycle is crucial.

The MoistTech IR3000 helps grain producers cut costs and increase end product quality. Compared to other grain moisture sensors, MoistTech’s carefully designed instrument is more energy efficient, and it reduces startup and downtimes. It eliminates grain waste due to excessive moisture content, as well as any profit lass due to an overly dry, or to wet product.

Minerals & Bulk Materials

Minerals & Bulk Materials

Moisture control in the mineral industry improves the overall quality of your product. When you use the MoistTech sensor you can lower energy costs, produce less waste, and have less downtime in your process. MoistTech’s experience in the industry and knowledge of requirements in the production process, allows sensor calibrations, measurement wavelengths, algorithms, and optical requirements to be preset by the company. MoistTech has thousands of installations worldwide in applications for monitoring and controlling moisture in a variety of minerals.

- Powder Bulk Solids Article _Dec 2019

- Moisture Content In Lime

- Fertilizer Moisture Management Article Jan 2021

MoistTech’s sensor can be used in all of these mineral applications:

Bauxite

Bentonite

Boric Acid

Cement

Ceramic Powder

Ceramics

Chalk

Clay

Coal

Copper Tailings

Crushed Limestone

Ferrite Powder

Fly Ash

Foundry Sand

Brick Clay Moisture

Glass

Glass Cullet

Gypsum

Iron Ore

Laminated Glass

Peat Moss

Perlite

Salt

Sand

Sinter Mix

Slag (Furnace)

Soda Ash

Sulfur

Titanium Dioxide

Zeolite

Zink Oxide

Sheetrock

Snack Foods

Knowing the moisture content of the materials used throughout the food making and baking processes as become one of the most critical components in the industry as many raw materials sold today are based on weight. Quick tests on moisture levesl of raw ingredients saves purchasing plants money.

The mixing stage also requires moisture content monitoring to ensure the consistency of an end product. Testing moisture during the mixing step of the process allows critical adustments to be made.

As taste, appearance, consistency, stability, and shelf life are all affected by the amount of water in a food product, sensing moisture throughout the food production process allows manufacturers to precisely control ovens, dryers, roasters and fryers to optimize their product quality.

Textile/Nonwoven

MoistTech-Full-Product-Catalog

Nonwovens & Textile Application Moisture Sensing VIDEO

Textile applications for the MoistTech sensor include:

Cotton

Wool

Leather

Linen

Acetate Tow

Rayon

Neoprene

Green Wood Chips

Nonwovens

PVB Plastic Pellets

Nylon Pellets

Nylon66

Fiberglass

Tobacco

MoistTech’s tobacco moisture sensor is considered by many to be the company’s flagship sensor. It offers unmatched performance for tobacco moisture measurement and control within all areas of the tobacco industry, offering the ability to monitor and control processes to within tenths of a percent.

Wood Products

Wood Products

MoistTech offers the most advanced wood moisture sensors for the non-contact measurement of moisture in forest products such as fiber, sawdust, hog fuel, wood flakes, and wood particles. Wood product manufacturers can use the NIR sensor to adjust moisture levels on realtime information, lowering raw material and fuel costs, producing higher yields, and more uniform products.